15 October, 2024

How to Design a Custom Lanyard: A Creative Guide

Designing a custom lanyard involves several critical features to ensure both functionality and aesthetic appeal. It's not just a matter of putting your logo on one, and away you go. There are many areas you need to consider to ensure you get the maximum usage and impact out of your custom-printed lanyard. Today we are going to look at the critical factors involved.

Material Selection

When selecting materials, it's crucial to consider both durability and comfort. Here are more details on the options:

Polyester

Durability: It is highly durable, resistant to stretching and shrinking, and retains its shape well.

Comfort: It's lightweight and has a smooth texture, making it comfortable to wear for extended periods.

Printing: Ideal for screen printing and dye sublimation, polyester allows vibrant colour reproduction and detailed designs.

Nylon

Durability: It is known for its exceptional strength and elasticity. It's more resilient than polyester, making it suitable for heavy-duty use.

Comfort: It has a slightly shinier and silkier texture than polyester, offering a more premium feel.

Printing: Nylon's smooth surface is excellent for high-quality, crisp printing, especially for intricate logos and text.

Woven Fabric

Durability: They are generally robust and maintain their structure even after continuous use.

Comfort: The woven texture gives a more organic feel, which can be more comfortable against the skin.

Customisation: They often feature embroidered designs, lending a sophisticated and high-quality appearance.

Additionally, consider the thickness of the material. Thicker ones can be more durable and provide a broader area for branding but may be less comfortable in warm environments. Conversely, thinner styles are lighter and can be more comfortable but might not have the same visual impact or durability.

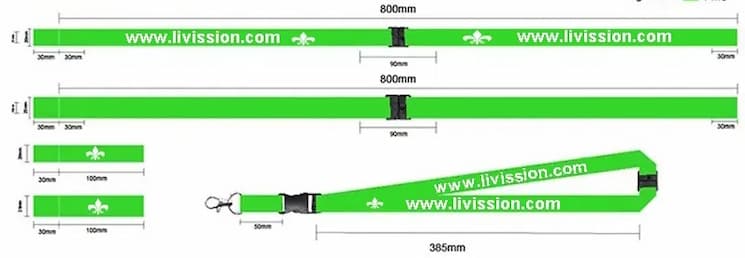

Lanyard Width and Length

The dimensions of the lanyard are essential for both functionality and aesthetics.

Width

Range: Typically, they come in widths of 15mm, 20mm and 25mm.

Usage: Wider lanyards (25mm) offer more space for branding and are more visible from a distance. They're often used for bold designs and prominent logos. Narrower lanyards (15mm) are more subtle and lightweight, suitable for minimalistic designs or when the lanyard shouldn't dominate the attire.

Comfort: Wider ones distribute the weight more evenly, which can be more comfortable if they hold heavier items like multiple keys or a large badge.

Length

Standard Length: The standard length for adult lanyards is usually between 90 to 100cm. This length allows the lanyard to hang comfortably at mid-torso when worn around the neck.

Custom Length: For children or specific use cases, custom lengths can be created. Shorter lengths are safer and more convenient for kids or for activities where a longer one might be cumbersome.

Usability: The length should be chosen keeping in mind the ease of use. For example, if it is used to display ID cards, it should be long enough for easy viewing but not so long that it becomes inconvenient to handle.

In both cases, the choice of width and length should align with the intended use, the target audience, and the overall design goals.

Colour Scheme

The colour scheme plays a significant role in its visual appeal and effectiveness in conveying a brand or event identity.

Representing a Brand or Event

Brand Identity: Choose colours that align with your brand's logo or theme. Consistent use of brand colours enhances recognition and reinforces brand identity.

Event Theme: For events, select colours that reflect the event's theme or purpose. For instance, bright, vibrant colours for a festival, or more subdued, professional tones for a corporate event.

Contrasting Colours

Readability: Use contrasting colours for the text and background to ensure the text is easily readable from a distance. For example, dark text on a light background or vice versa.

Visual Appeal: Contrasting colours can make the lanyard more visually striking. However, it’s important to balance contrast with aesthetic harmony to avoid clashing colours.

Colour Psychology

Emotional Impact: Different colours can evoke different emotions. For example, blue can convey trust and dependability, while red can signify energy and urgency.

Target Audience: Consider the preferences and perceptions of your target audience. Cultural significance of colours should also be taken into account.

Special Finishes

Reflective or Neon Colours: For added visibility or safety, especially in low-light conditions.

Metallic or Glitter Finishes: To add a premium or festive touch.

Logo and Text Placement

Effective placement of logos and text is key to its functionality as a branding tool.

Logo Placement

Visibility: Position the logo in a prominent place, typically at the centre or repeated along the length, ensuring it is visible when worn.

Size and Proportion: The logo size should be balanced with the lanyard's width. A larger logo on a wider one for impact, and a smaller, subtler logo on narrow lanyards.

Text Legibility

Font Size and Style: Choose a font size that is easily readable. The style should be clear and straightforward, avoiding overly decorative fonts that might reduce readability.

Scaling: Text should be scaled to fit the lanyard size without appearing cramped or stretched. It’s important that all text, including smaller details, is legible.

Repeated Design

For continuous visibility, consider a repeating design where the logo and text appear at intervals along the entire length. Ensure that the repeated elements are aligned in a way that maintains the design's integrity, regardless of how the lanyard is worn.

Alignment and Orientation

Alignment: Centre alignment is commonly used for simplicity and balance, but consider other alignments based on the design.

Orientation: The orientation of the logo and text should be such that it appears upright and readable when it is worn.

Printing Method

The printing method chosen significantly affects its appearance, durability, and cost.

Screen Printing

Process: Involves pushing ink through a woven mesh stencil onto the fabric.

Suitability: Best for simple designs with few colours. Ideal for bold, solid colours and basic text or logos.

Durability: Offers good durability, with the ink adhering well to the material.

Cost: Generally more cost-effective for larger quantities with less complex designs.

Dye Sublimation

Process: Uses heat to transfer dye onto the material, allowing for full-colour, edge-to-edge printing.

Suitability: Perfect for complex designs and gradients, as it can reproduce a wide range of colours with high detail.

Durability: Produces a high-quality print that is less prone to fading and wear.

Cost: Tends to be more expensive, but offers superior results for intricate, colourful designs.

Woven Designs

Process: Involves weaving the design directly into the fabric using coloured threads.

Suitability: Ideal for simple, text-based designs or basic logos. Offers a textured, premium look.

Durability: Extremely durable, as the design is an integral part of the fabric.

Cost: Can be more costly due to the complex manufacturing process, especially for detailed designs.

Attachment Type

The choice of attachment is crucial for its functionality and user convenience:

J-Hooks

Use: Commonly used for holding ID cards or keys.

Advantages: Easy to attach and detach items; widely compatible with different types of badge holders.

Bulldog Clips

Use: Best suited for clipping onto ID card slots or pre-punched holes.

Advantages: Offers a secure grip and is easy to use, ideal for quick access to the attached item.

Key Rings

Use: Perfect for holding keys or small tools.

Advantages: Provides a secure way to keep keys in place; durable and versatile.

Breakaway Features

Safety: Essential for environments where there is a risk of the lanyard getting caught or pulled, such as in schools, factories, or hospitals.

Design: Typically involves a clasp or connector that easily breaks apart when under pressure but can be reconnected afterwards.

Consideration: Important for compliance with certain safety regulations and standards.

Each attachment type serves a specific function and should be chosen based on the intended use of the lanyard. The incorporation of safety features like breakaway clasps is critical in environments where safety is a priority. Balancing functionality, safety, and aesthetic appeal is key in selecting the right attachment for your custom lanyard.

Additional Features:

Incorporating additional features into the design can enhance both its functionality and safety.

Safety Breakaways

Function: These are detachable connectors that release the lanyard if it's pulled with force, reducing the risk of injury.

Importance: Essential in environments where they might get caught (like machinery in factories or during physical activities in schools).

Design: Typically a small, easily reconnectable clip located at the back of the neck.

Buckles

Function: Allow the bottom part of the lanyard to be detached and reattached quickly.

Usefulness: Ideal for situations where the attached items (like keys or ID cards) need to be used frequently without removing the entire lanyard.

Varieties: Come in different forms, such as plastic side-release buckles or metal snap buckles.

Badge Holders

Integration: Can be an integral part of the design, especially for events and corporate settings.

Types: Rigid card holders for more durability or flexible plastic pouches for easy insertion and removal of IDs or badges.

Customisation: Can be custom-sized to fit specific badge dimensions.

Reflective Material or Glow-in-the-Dark Features

Visibility: Enhance visibility in low-light conditions, crucial for safety in certain environments like construction sites or during nighttime events.

Application: Reflective stripes or coatings, and materials that glow in the dark after being exposed to light.

Aesthetics: Adds a distinctive look, which can also be appealing for style or branding purposes.

Customisation Options

Customisation is key to creating one that is both unique and aligned with specific branding or personal preferences:

Double-Sided Printing

Flexibility: Allows different designs on each side, maximising branding or design space.

Application: Useful for displaying different information or languages on each side.

Unique Shapes

Variety: They can be custom-cut into various shapes, breaking away from the traditional flat design.

Purpose: Shapes can reflect brand identity, such as one shaped to mimic a product or logo.

Eco-Friendly Materials

Sustainability: Options like recycled polyester, bamboo fibre, or organic cotton reduce environmental impact.

Branding: Aligns with and promotes a brand's commitment to sustainability, appealing to environmentally conscious consumers.

Performance: These materials often match the durability and print quality of traditional materials.

Recyclable Components

End-of-Life: Using materials that can be easily recycled, ensuring it doesn't end up as waste.

Awareness: Promotes environmental awareness and responsibility.

By exploring these additional features and customisation options, they can be tailored not only to specific aesthetic and functional requirements but also to safety standards and environmental considerations, adding significant value and appeal.

Proofing and Mock-ups:

The process of proofing and creating mock-ups is an essential step in the design process. It ensures the final product meets your expectations and requirements.

Digital Proof

Purpose: Provides a visual representation of the final product.

Details to Check: Confirm the accuracy of colours, font sizes, logo dimensions, and overall layout.

Revisions: Allows for adjustments and corrections before proceeding to production.

Speed: They are quick to produce and easy to modify, making them ideal for initial approvals.

Physical Sample

Realistic Representation: Offers a tangible example of how it will look and feel.

Material and Print Quality: Allows you to assess the material quality, print clarity, and durability.

Colour Accuracy: Essential for confirming that the colours match your brand or design specifications, as screen displays can sometimes be misleading.

Additional Cost and Time: Physical samples may involve additional costs and production time but are worthwhile for large orders or when exact specifications are critical.

Overall Design Verification

Alignment and Spacing: Ensure that text and logos are properly aligned and spaced.

Functional Aspects: Check attachment points, safety features, and any additional elements like buckles or badge holders.

Final Approval: Only after thorough verification should the design be approved for final production.

Budget and Quantity

Balancing the budget and the quantity needed is a critical aspect of the production.

Quantity and Price Per Unit

Volume Discount: Larger orders typically reduce the cost per unit due to economies of scale in production.

Minimum Order Quantity: Be aware of minimum order requirements, as some manufacturers may have set limits.

Balancing Quality and Cost

Material Selection: Higher quality materials may cost more, but offer better durability and appearance.

Printing Methods: More complex printing methods like dye sublimation are more expensive but offer superior results. Screen printing may be more cost-effective for simpler designs.

Custom Features: Additional features like unique shapes or eco-friendly materials can impact cost.

Budget Planning

Estimate Costs: Get quotes from different suppliers to compare prices.

Consider All Expenses: Include potential costs for design, proofing, and shipping in your budget.

Quality vs. Price: Decide on the importance of quality versus cost. For high-profile events or long-term use, investing in higher quality may be beneficial.

Flexibility

Adjusting Specifications: If budget constraints arise, consider adjusting the design, reducing the number of colours, or changing materials to lower costs.

Order Phases: For large quantities, consider phasing the order to spread out costs.

Delivery Timeline:

Managing the delivery timeline is a critical aspect of the ordering process. It involves careful planning and coordination to ensure the lanyards are delivered on time for your event or needs.

Production Time

Estimation: Ask the manufacturer for an estimated production time. This can vary depending on the complexity of the design, the printing method, and the quantity ordered.

Manufacturing Process: The production time includes everything from the finalisation of the design, the actual manufacturing process, to the quality checks.

Buffer Period: Always include a buffer period in your timeline for any unforeseen delays in production.

Shipping Time

Shipping Options: Determine the shipping method (standard, express, overnight) based on how quickly you need them.

Location Impact: The shipping duration can vary greatly depending on the location of the manufacturer and the delivery destination.

Tracking and Updates: Opt for shipping methods that provide tracking and regular updates to monitor the progress of your shipment.

Rush Orders

Feasibility: In situations where they are needed urgently, inquire about rush orders. Note that not all manufacturers may be able to accommodate rush requests.

Additional Costs: Rush orders often come with additional costs. These can be significantly higher than standard orders due to the expedited production and shipping.

Quality Consideration: While rush orders are faster, ensure this doesn't compromise the quality of the final product.

Contingency Planning

Plan B: Always have a backup plan in case of delays. This could include having an alternative supplier or a different type of event badge available.

Communication: Maintain clear communication with the manufacturer about your timeline requirements. Inform them of the event date or any deadlines to align expectations.

Ordering in Advance

Early Planning: To avoid the need for rush orders, plan and place your order well in advance of your event.

Review and Adjustments: Early ordering allows time for reviewing proofs, making adjustments, and addressing any issues without the pressure of an approaching deadline.

Effectively managing the delivery timeline involves planning for both production and shipping time, considering the possibility and implications of rush orders, and having contingency plans in place. Early planning and clear communication with the manufacturer are key to ensuring timely delivery.

Final Thought

There you have it. Everything you need to design the perfect lanyard. Remember, a well-designed one not only serves a practical purpose but also acts as a branding tool, so it's important to give due attention to each of these elements.

The Lanyards Only Team